Categories

- Automobile Bins Washer

- Bucket Washer

- Can Washer

- Crab Washer

- Crate Washer

- Cylinder Washer

- Dishes & Bowls Washer

- Drum Washer

- Egg Tray Washer

- Ice Cream Crates Washer

- Incline Crate Washer

- Industrial Component Washer

- LPG Cylinder Washer

- Pallet Washer

- Steam Washer

- Tin Cooling Conveyor

- Tray Washer

- Utensil Washer

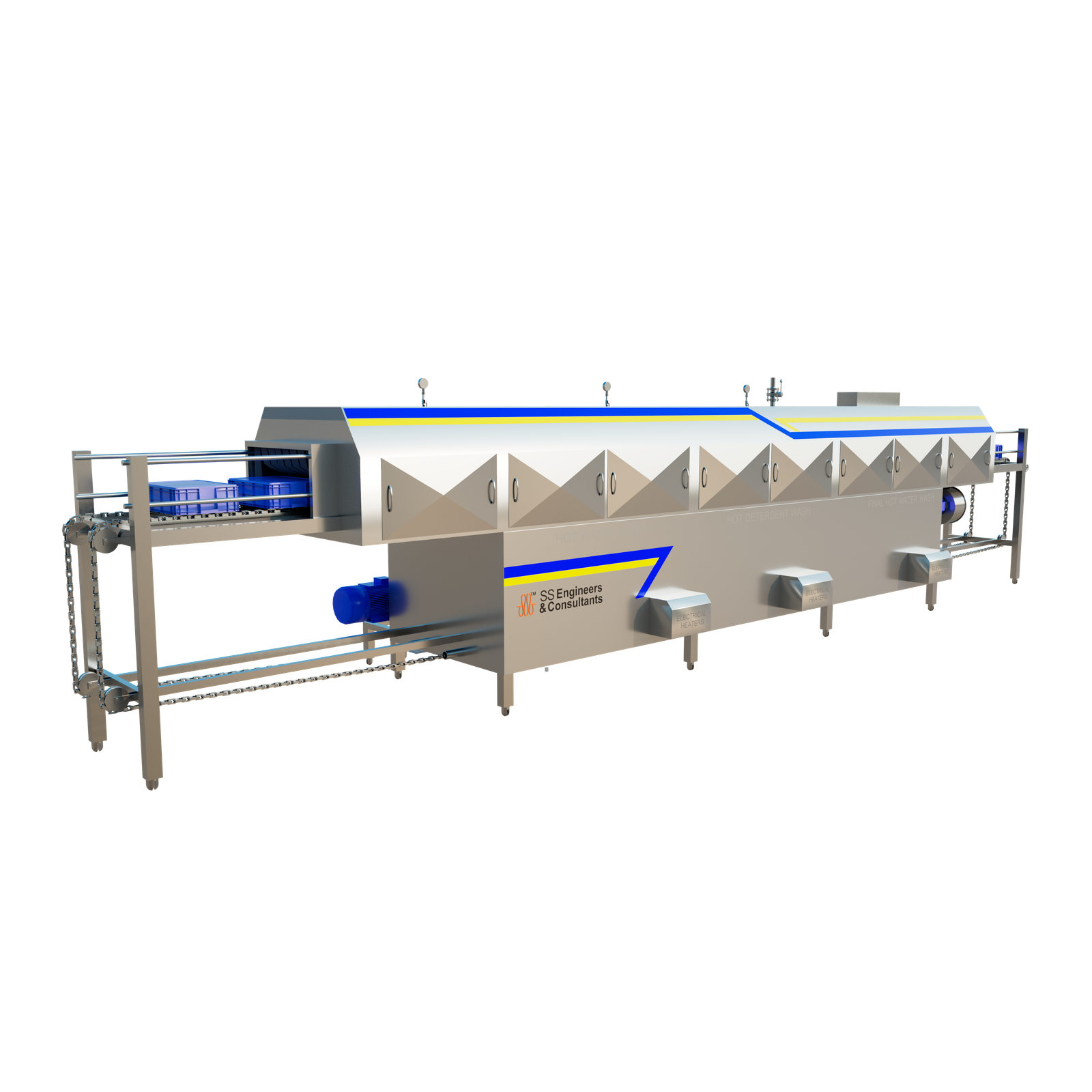

Tray Washer

Unlock the power of SS Engineers’ advanced Tray Washer solutions by reaching out for a tailored quotation. Our state-of-the-art washing systems are designed to efficiently clean everything, from transportation and packing crates to production line crates and utensils, ensuring optimal performance across a range of applications.

Transform your material handling process with SS Engineers’ customizable solutions. Our Tray Washer systems seamlessly integrate into your workflow, enhancing operational efficiency and addressing the unique cleaning needs of your industry. Contact us today to get started!

Key Features:

- Durable stainless-steel construction ensuring hygiene, durability, and corrosion resistance

- Automated high-pressure washing system for efficient cleaning of trays used in food, bakery, dairy, and industrial applications

- Rotary nozzles and jet sprays designed to remove dirt, grease, oil, stains, and product residues from trays

- Adjustable conveyor system for smooth loading, washing, rinsing, and unloading of trays with minimal manual handling

- Advanced water filtration and recycling system ensuring energy- and water-efficient operation

- Modular design adaptable for various tray sizes, shapes, and production capacities

- Compatible with detergent dosing, rinsing, and hot air drying systems for complete tray cleaning solutions

- Designed to maintain hygiene standards, improve productivity, and ensure safe, sanitized trays for reuse

See it in Action

Youtube Video Auto Playing without sound