Products & Services >> Dairy Plant & Machinery >> Yogurt Curd Processing Plant

SS Engineers & Consultants delivered a cutting-edge yogurt processing plant tailored to meet international standards and the high demand for quality fermented products in the Australian market.

=> Milk pasteurizer

=> Homogenizer for uniform texture

=> Fermentation tanks with precise temperature control

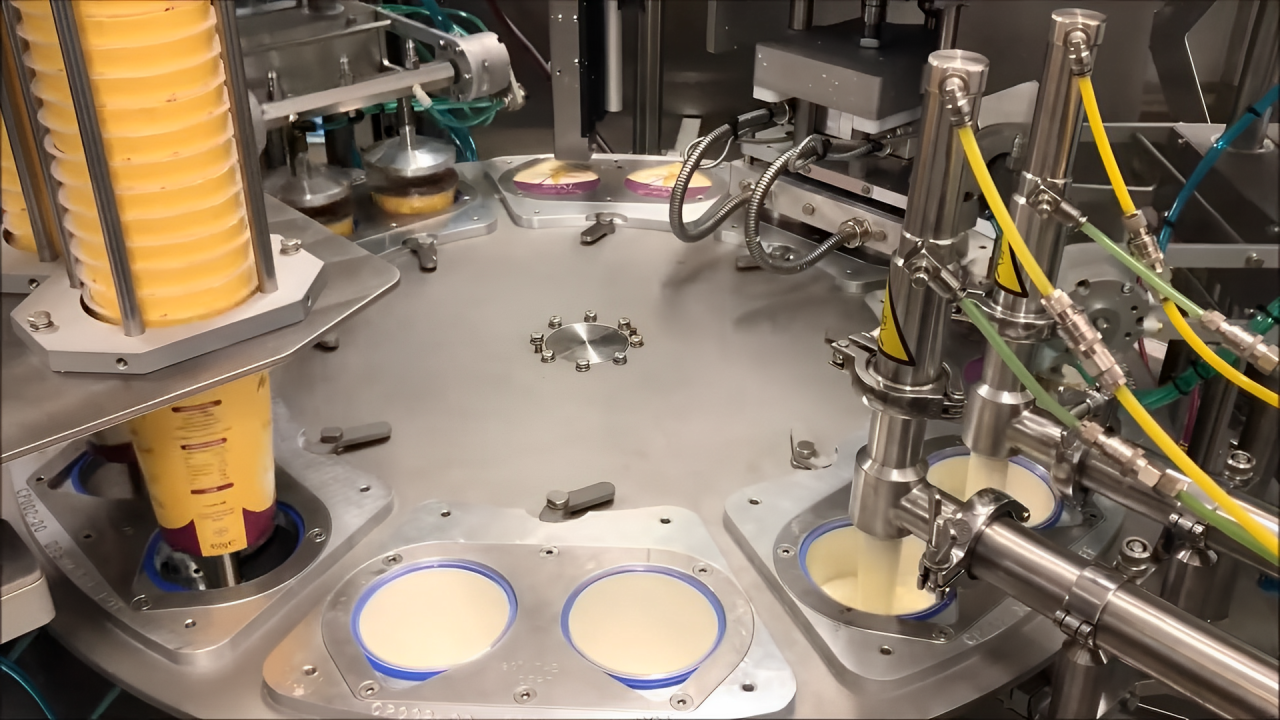

=> Yogurt filling and sealing line with tamper-evident packaging

=> Fully automated CIP systems

=> PLC-based controls for seamless operation

=> Customized fermentation tanks for varied product viscosities

=> Energy-efficient cooling systems for rapid chilling post-fermentation

=> Integration with cold storage facilities for extended product shelf life

A modern cheese processing plant designed to produce high-quality soft and hard cheese varieties for the Indian market, catering to both domestic consumption and export.

=> Milk coagulation vats

=> Cheese curd processing lines with cutting, pressing, and molding units

=> Salting and curing chambers

=> Vacuum packaging systems for longer shelf life

=> PLC-integrated control panels for precise processing and consistent quality

=> Advanced coagulation vats for optimal curd yield

=> Hygienic conveyor systems for cheese handling and processing

=> Climate-controlled curing chambers for uniform ripening

Paneer processing plants designed for small-scale to industrial production capacities, ensuring consistent quality and high production efficiency.

=> Milk coagulation tanks

=> Paneer pressing and cutting machines

=> Paneer chilling and packaging units

=> Steam boilers and hot water systems for efficient processing

Semi-automated to fully automated options based on client requirements

=> Customizable pressing systems for varying paneer textures

=> Hygienic chilling systems for quick cooling to maintain freshness

=> Compact layouts for space optimization in smaller facilities

=> Comprehensive site assessments to ensure readiness for utilities such as steam, power, and drainage.

=> Tailored guidance for optimal plant layouts and workflows.

=> Strategic positioning of key equipment for seamless operations.

=> Focus on ergonomic design and adherence to global hygiene standards.

=> Expert technicians ensuring precision in equipment installation.

=> Rigorous testing to validate performance and compliance with quality standards.

=> Pasteurizers: efficient heat treatment of milk.

=> Fermentation Tanks: Precise control of temperature and timing for optimal results.

=> Homogenizers: Ensuring uniform texture in yogurt and cheese.

=> Curd Processing Units: Automated cutting, pressing, and molding systems.

=> Packaging Lines: High-speed filling and sealing units for yogurt, cheese, and paneer.

=> CIP Systems: Integrated cleaning systems for hygiene compliance.

=> Expertise in fermented product processing plants, from yogurt to paneer.

=> Tailored solutions to meet diverse production requirements.

=> Proven track record of successful installations globally.

Get in touch with SS Engineers & Consultants today for innovative and efficient dairy processing solutions!